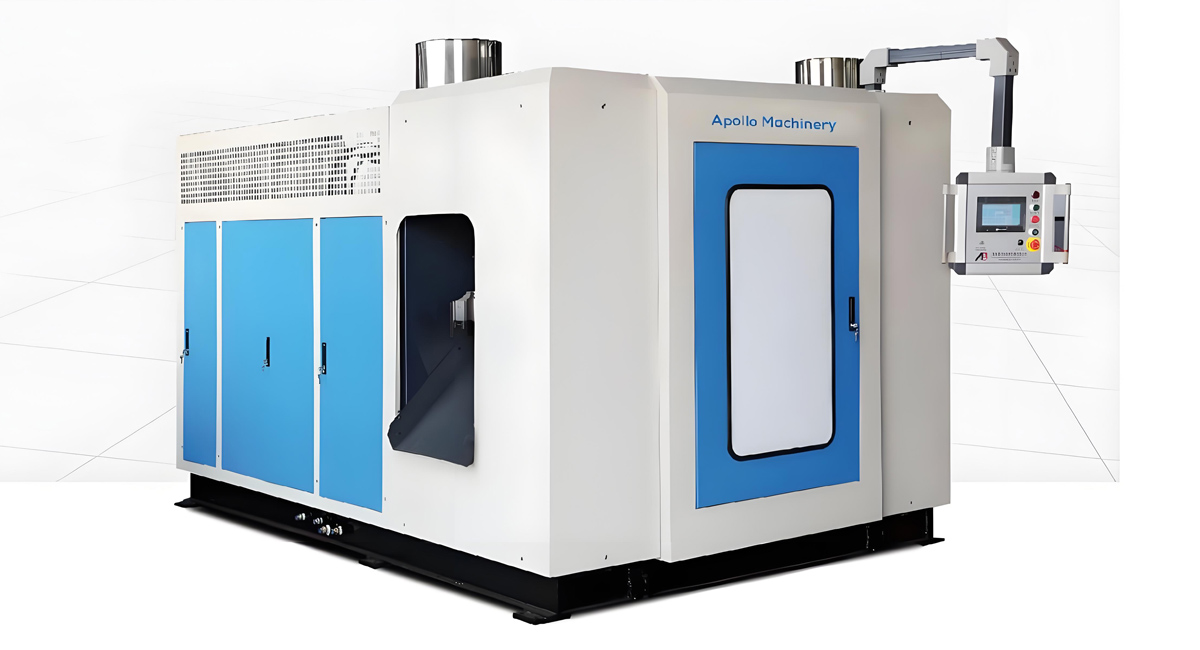

Apollo

ABLB Series (200ML-20L)

Apollo ABLB Series (200ML-20L) single station and double station series high-speed extrusion blow molding machines can be used to produce containers with capacities of 200ML-20L. The single station can produce up to 1550 pieces per hour, while the double station can produce up to 1900 pieces per hour.

-

ABLB 45 (1L-2L)

Name Units ABLB 45 I ABLB 45 II Max. product volume L 2 1 Dry cycle PC/H 1550 700*2 Screw diameter MM 45 45 Screw L/D ratio L/D 24 24 Screw drive power KW 11 11 Screw heating capacity KW 3-4 3-4 No. of heating zone ZONE 3 3 Output of HDPE KG/H 30 30…

-

ABLB 55 (2L-3L)

Name Units ABLB 55 I ABLB 55 II Max. product volume L 3 2 Dry cycle PC/H 110 950*2 Screw diameter MM 55 55 Screw L/D ratio L/D 24 24 Screw drive power KW 15 15 Screw heating capacity KW 5-6 5-6 No. of heating zone ZONE 3 3 Output of HDPE KG/H 60 60…

-

ABLB 65 (3.5L-5L)

Name Units ABLB 65 I ABLB 65 II Max. product volume L 5 3.5 Dry cycle PC/H 1000 800*2 Screw diameter MM 65 65 Screw L/D ratio L/D 24 24 Screw drive power KW 18.5 18.5 Screw heating capacity KW 5-6 5-6 No. of heating zone ZONE 3 3 Output of HDPE KG/H 75 75…

-

ABLB 75 (8L)

Name Units ABLB 75 I ABLB 75 II Max. product volume L 8 8 Dry cycle PC/H 800 800*2 Screw diameter MM 75 75 Screw L/D ratio L/D 24 24 Screw drive power KW 22 22 Screw heating capacity KW 7-8 7-8 No. of heating zone ZONE 4 4 Output of HDPE KG/H 100 100…

-

ABLB 80 (10L)

Name Units ABLB 80 I ABLB 80 II Max. product volume L 10 10 Dry cycle PC/H 700 700*2 Screw diameter MM 80 80 Screw L/D ratio L/D 24 24 Screw drive power KW 30 37 Screw heating capacity KW 8-9 8-9 No. of heating zone ZONE 4 4 Output of HDPE KG/H 110 120…

-

ABLB 90 (16L)

Name Units ABLB 90 I ABLB 90 II Max. product volume L 16 16 Dry cycle PC/H 800 500*2 Screw diameter MM 90 90 Screw L/D ratio L/D 24 24 Screw drive power KW 37 45 Screw heating capacity KW 10 12 No. of heating zone ZONE 4 4 Output of HDPE KG/H 130 150…

-

ABLB 100 (30L)

Name Units ABLB 100 I ABLB 100 II Max. product volume L 30 30 Dry cycle PC/H 400 400*2 Screw diameter MM 100 100 Screw L/D ratio L/D 25 25 Screw drive power KW 55 55 Screw heating capacity KW 15 15 No. of heating zone ZONE 4 4 Output of HDPE KG/H 200 200…

-

ABLB 82 PC Material (25L)

Features Equiped with Japanese Mitsubishi PLC & temperature controller, Schneider contactor, Delta or ABB invertor, Siemens Motor, HITECH oil pump, Original Japan MOOG 100 points parison controller. Die head inner runner adopt special steel mirror treatment, make sure PC products smooth surface and its transparent. Mould temperature controller and neck cutting device is equiped special…

Features

Servo system: Optional hydraulic servo system.

Electrical control system: It is controlled by imported PLC and man-machine interface (in Chinese or English) and operated by color touch screen, All process setting, changing. searching, monitoring, and trouble diagnosis can be done on the touch screen, Non-contact working principle, the components are endurable.

Hydraulic system: It is controlled by proportional pressure and is provided with YUKEN hydraulic components, so it is consistent and reliable.

Plasticization system: Eficient plasticization twin-screw ensures sufficient and even plasticization.

Speed regulating system: Frequency variable regulating + alloy steel hard finishing reducer steadily regulate speed with low noise, so they are endurable.

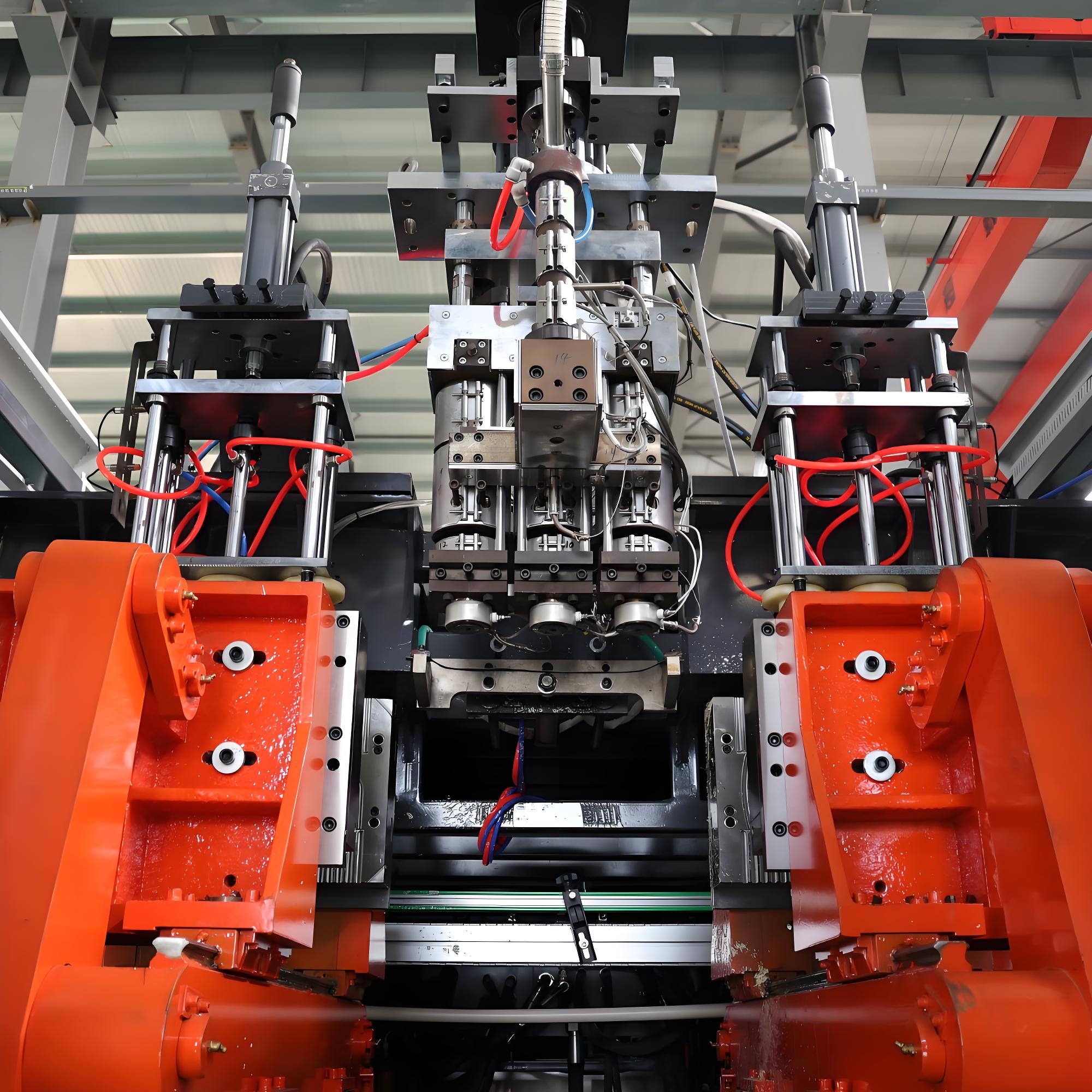

Clamping system and die shifting system: Die shifting and clamping are done by clamping mechanism with double straight line trail, so it has high accuracy, low resistance and high speed.

Contact Apollo Engineer

If you are interested in our company and machine, feel free to contact our sales engineer. We will contact you as soon as possible.

Contact Us

Our sales engineer will contact you in 24 hours, we focus on the extrusion blow moulding machine for more than 20 years.

E-mail:

Phone:

008615950512730 (Whatsapp)

Address:

Hongqi Bridge, Tianzhuang Villiage of Fenghuang Town, Zhangjiagang City, Jiangsu Province, China