Fitur

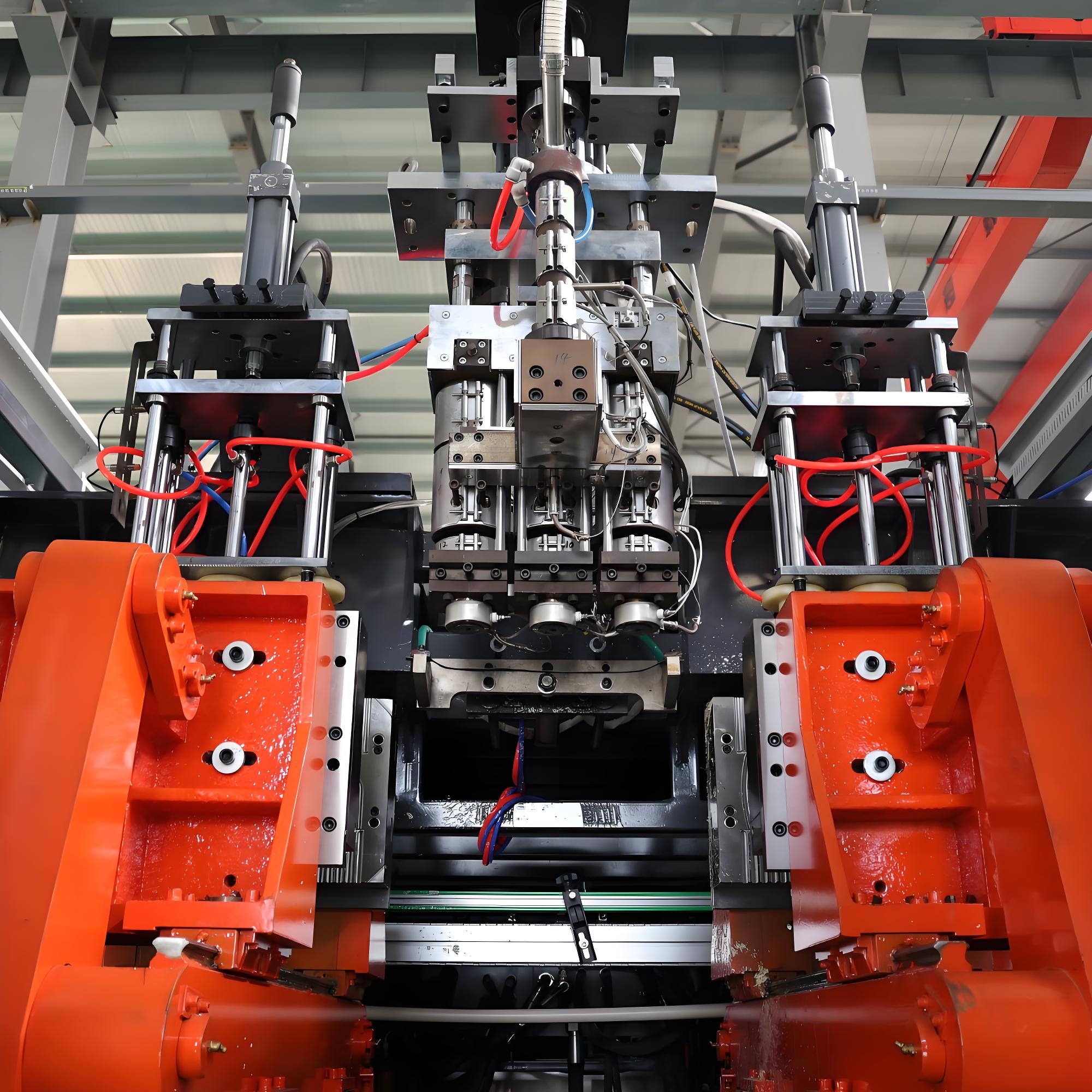

Equiped with Japanese Mitsubishi PLC & temperature controller, Schneider contactor, Delta or ABB invertor, Siemens Motor, HITECH oil pump, Original Japan MOOG 100 points parison controller.

Die head inner runner adopt special steel mirror treatment, make sure PC products smooth surface and its transparent.

Mould temperature controller and neck cutting device is equiped special for PC products.

Parameter terperinci

| Nama | Unit | ABLB 82 PC |

| Maks. volume produk | L | 25 |

| Siklus kering | PC / H | 360 |

| Diameter sekrup | MM | 82 |

| Rasio L/D sekrup | L/D | 25/30 |

| Daya penggerak sekrup | KW | 10-80 |

| Kapasitas pemanasan sekrup | KW | 30 |

| Jumlah zona pemanasan | ZONA | 5 |

| Output of PC | KG / H | 160 (PC) |

| Daya penggerak pompa oli | KW | 45*2 |

| Kekuatan penjepit | KN | 220 |

| Maks. ukuran cetakan | MM | 1000×1600 |

| Template sze | MM | 800×800 |

| Die head heating power | KM | 8.7 |

| Total power consumption | KM | 83 |

| Meniupkan tekanan | KG/CMZ | 8 |

| Volume udara | M³ / MIN | 0.8 |

| Cooling water temperature | ℃ | 5-10℃ |

| Average power consumption | KW | 42 |

| Ukuran mesin | LxWxH | 5.6×2.7×4.5 |

| Berat mesin | TON | 11.8 |