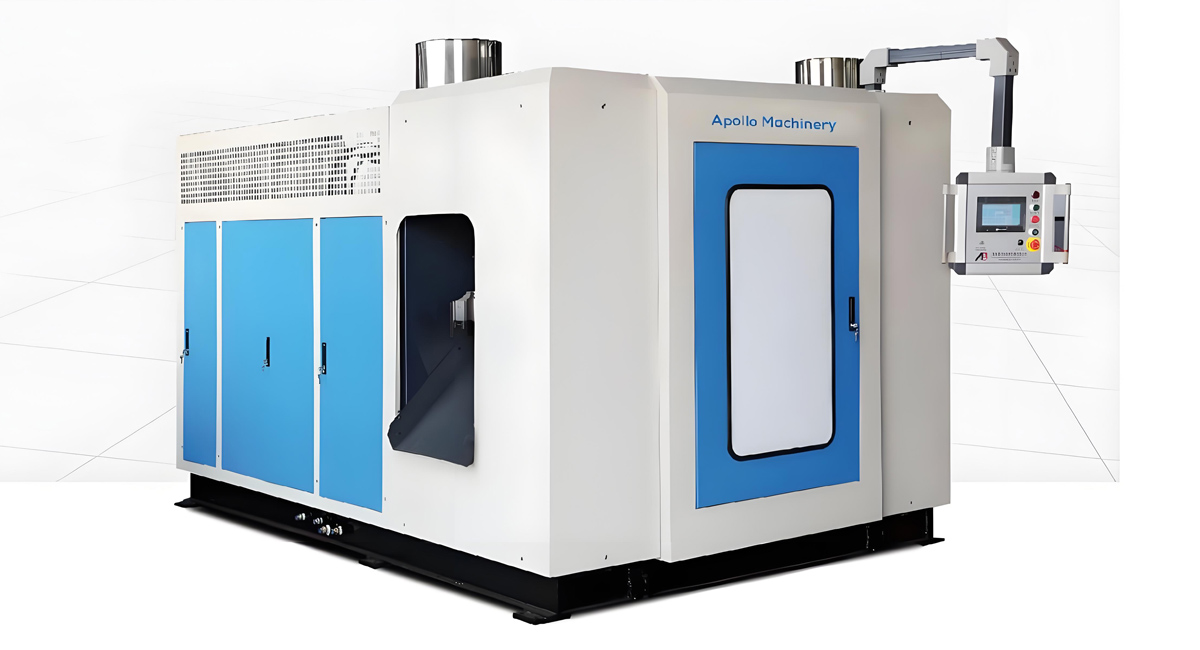

Apollo

Siri ABLB (200ML-20L)

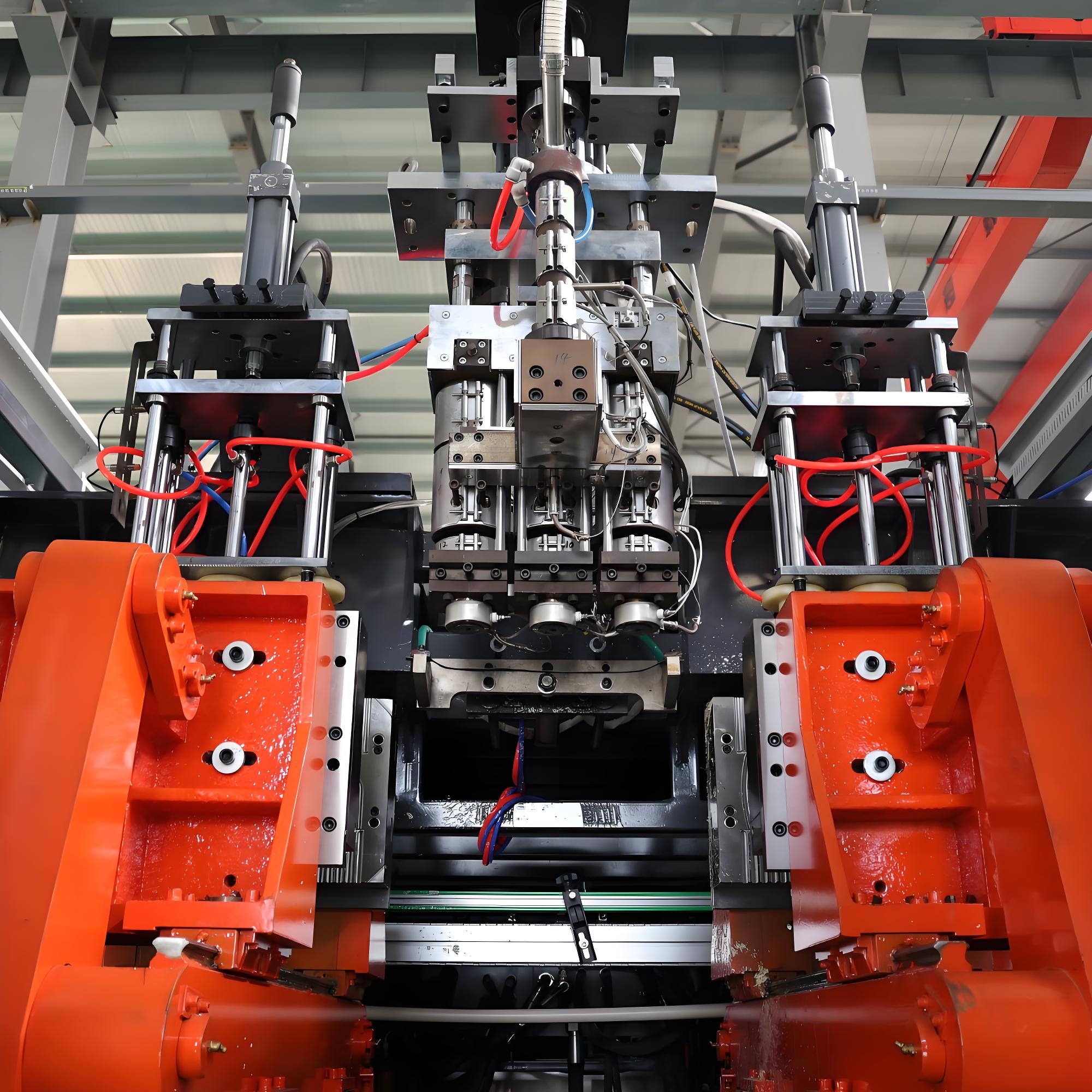

Apollo ABLB Series (200ML-20L) single station and double station series high-speed extrusion blow molding machines can be used to produce containers with capacities of 200ML-20L. The single station can produce up to 1550 pieces per hour, while the double station can produce up to 1900 pieces per hour.

-

ABLB 45 (1L-2L)

Nama Unit ABLB 45 I ABLB 45 II Maks. isipadu produk L 2 1 Kitaran kering PC/H 1550 700*2 Diameter skru MM 45 45 Nisbah L/D Skru L/D 24 24 Kuasa pemacu skru KW 11 11 Kapasiti pemanasan skru KW 3-4 3-4 Bilangan zon pemanasan ZON 3 3 Output HDPE KG/H 30 30…

-

ABLB 55 (2L-3L)

Nama Unit ABLB 55 I ABLB 55 II Maks. isipadu produk L 3 2 Kitaran kering PC/H 110 950*2 Diameter skru MM 55 55 Nisbah L/D Skru L/D 24 24 Kuasa pemacu skru KW 15 15 Kapasiti pemanasan skru KW 5-6 5-6 Bilangan zon pemanasan ZON 3 3 Output HDPE KG/H 60 60…

-

ABLB 65 (3.5L-5L)

Nama Unit ABLB 65 I ABLB 65 II Maks. isipadu produk L 5 3.5 Kitaran kering PC/H 1000 800*2 Diameter skru MM 65 65 Nisbah L/D Skru L/D 24 24 Kuasa pemacu skru KW 18.5 18.5 Kapasiti pemanasan skru KW 5-6 5-6 Bilangan zon pemanasan ZON 3 3 Output HDPE KG/H 75 75…

-

ABLB 75 (8L)

Nama Unit ABLB 75 I ABLB 75 II Maks. isipadu produk L 8 8 Kitaran kering PC/H 800 800*2 Diameter skru MM 75 75 Nisbah L/D Skru L/D 24 24 Kuasa pemacu skru KW 22 22 Kapasiti pemanasan skru KW 7-8 7-8 Bilangan zon pemanasan ZON 4 4 Output HDPE KG/H 100 100…

-

ABLB 80 (10L)

Nama Unit ABLB 80 I ABLB 80 II Maks. isipadu produk L 10 10 Kitaran kering PC/H 700 700*2 Diameter skru MM 80 80 Nisbah L/D Skru L/D 24 24 Kuasa pemacu skru KW 30 37 Kapasiti pemanasan skru KW 8-9 8-9 Bilangan zon pemanasan ZON 4 4 Output HDPE KG/H 110 120…

-

ABLB 90 (16L)

Nama Unit ABLB 90 I ABLB 90 II Maks. isipadu produk L 16 16 Kitaran kering PC/H 800 500*2 Diameter skru MM 90 90 Nisbah L/D Skru L/D 24 24 Kuasa pemacu skru KW 37 45 Kapasiti pemanasan skru KW 10 12 Bilangan zon pemanasan ZON 4 4 Output daripada HDPE KG/H 130 150…

-

ABLB 100 (30L)

Nama Unit ABLB 100 I ABLB 100 II Maks. isipadu produk L 30 30 Kitaran kering PC/H 400 400*2 Diameter skru MM 100 100 Nisbah L/D Skru L/D 25 25 Kuasa pemacu skru KW 55 55 Kapasiti pemanasan skru KW 15 15 Bilangan zon pemanasan ZON 4 4 Keluaran daripada HDPE KG/H 200 200…

-

Bahan PC ABLB 82 (25L)

Ciri-ciri Dilengkapi dengan Mitsubishi PLC Jepun & pengawal suhu, penyentuh Schneider, penyongsang Delta atau ABB, Siemens Motor, pam minyak HITECH, pengawal parison 100 mata MOOG Jepun Asal. Pelari dalaman kepala mati mengamalkan rawatan cermin keluli khas, pastikan produk PC permukaan licin dan telus. Pengawal suhu acuan dan peranti pemotong leher dilengkapi…

Features

Servo system: Optional hydraulic servo system.

Electrical control system: It is controlled by imported PLC and man-machine interface (in Chinese or English) and operated by color touch screen, All process setting, changing. searching, monitoring, and trouble diagnosis can be done on the touch screen, Non-contact working principle, the components are endurable.

Hydraulic system: It is controlled by proportional pressure and is provided with YUKEN hydraulic components, so it is consistent and reliable.

Plasticization system: Eficient plasticization twin-screw ensures sufficient and even plasticization.

Speed regulating system: Frequency variable regulating + alloy steel hard finishing reducer steadily regulate speed with low noise, so they are endurable.

Clamping system and die shifting system: Die shifting and clamping are done by clamping mechanism with double straight line trail, so it has high accuracy, low resistance and high speed.

Hubungi Jurutera Apollo

Jika anda berminat dengan syarikat dan mesin kami, sila hubungi jurutera jualan kami. Kami akan menghubungi anda secepat mungkin.

Hubungi Kami

Jurutera jualan kami akan menghubungi anda dalam masa 24 jam, kami memberi tumpuan kepada mesin pengacuan tamparan penyemperitan selama lebih daripada 20 tahun.

E-mel:

telefon:

008615950512730 (Whatsapp)

Alamat:

Jambatan Hongqi, Villiage Tianzhuang of Fenghuang Town, Zhangjiagang City, Jiangsu Province, China