Extrusion blow molding machines are widely used, and the following are some of the main application areas:

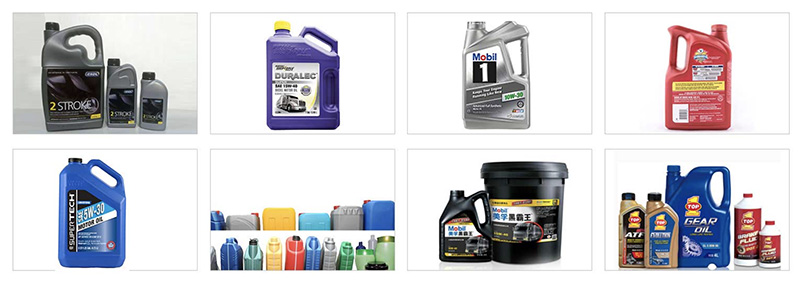

Packaging industry

Food packaging: used for producing various food containers, such as beverage bottles, edible oil bottles, seasoning bottles, etc. These bottles have good sealing and freshness, which can effectively prevent food from spoiling and extend shelf life. At the same time, different plastic materials and bottle designs can be selected according to the needs of different foods

Packaging for daily chemical products, such as shampoo, shower gel, laundry detergent, etc., is usually produced using extrusion blow molding technology. Diversified bottle shapes and exterior designs can be achieved to attract consumers’ attention and enhance product competitiveness

Pharmaceutical packaging: Some pharmaceutical packaging bottles, such as oral medication bottles, health product bottles, etc., are also produced using extrusion blow molding machines. Medical packaging requires high sealing, hygiene, and stability of containers, and extrusion blow molding technology can meet these requirements to ensure the quality and safety of drugs

Automotive industry

Automotive fuel tank: The extrusion blow molding machine can produce plastic automotive fuel tanks. Compared with traditional metal fuel tanks, it has the advantages of light weight, corrosion resistance, and low cost, which helps to reduce the weight and production cost of automobiles. At the same time, it can also meet the sealing and safety requirements of automotive fuel systems

Automotive air duct: used to manufacture air ducts in automotive ventilation systems, such as air conditioning ducts, intake ducts, etc. These air ducts need to have a certain degree of flexibility and sealing to ensure smooth air circulation inside the car and the normal operation of the air conditioning system

Other automotive parts: We can also produce accessories such as fuel pipes, plastic vents, and mudguards for cars. These plastic products are widely used in cars and can replace some metal parts, improving the production efficiency and performance of cars

Chemical industry

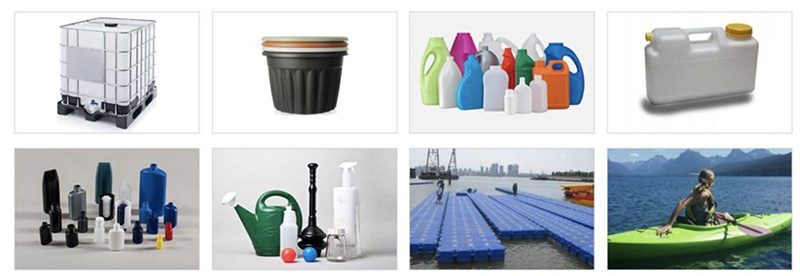

Chemical drums: Common types include 200L food grade plastic barrels, 220L double L ring chemical packaging barrels, open barrels, 2000L IBC tanks, etc., used for storing and transporting various chemical raw materials, coatings, adhesives, and other chemicals. Chemical drums need to have good corrosion resistance and sealing to prevent chemical leakage and contamination

Plastic storage tank: It can be used to manufacture large plastic storage tanks, chemical raw material storage tanks, etc., for storing large amounts of liquid or solid materials. Plastic storage tanks have the advantages of light weight, easy installation, and corrosion resistance, and are widely used in chemical production and storage

Medical industry

Medical devices: The shells or components of certain medical devices, such as medical oxygen masks, infusion bottles, syringe shells, etc., can be produced through extrusion blow molding technology. These products need to comply with strict medical standards to ensure their sterility, safety, and reliability

Drug packaging: In addition to the drug packaging bottles mentioned above, some special drug packaging, such as multi-layer co extruded infusion bags, also use extrusion blow molding technology. Multi layer co extruded infusion bags have good barrier properties and flexibility, which can better protect the quality of drugs

Household products

Plastic furniture: such as plastic chairs, tables, storage boxes, etc., extrusion blow molding machines can produce plastic furniture components of various shapes and sizes, which are then assembled or welded into complete furniture products. Plastic furniture has the advantages of being lightweight, durable, waterproof, and easy to clean, and is deeply loved by consumers

Daily necessities: including water buckets, trash cans, laundry detergent buckets, hand sanitizer buckets, etc. These products have a high demand, and extrusion blow molding technology can achieve efficient production and meet market demand

Toy industry

We can produce various plastic toys, such as hollow balls, plastic dolls, toy car shells, etc. The extrusion blow molding process can give toys rich shapes and colors while ensuring their safety and durability

Додатки