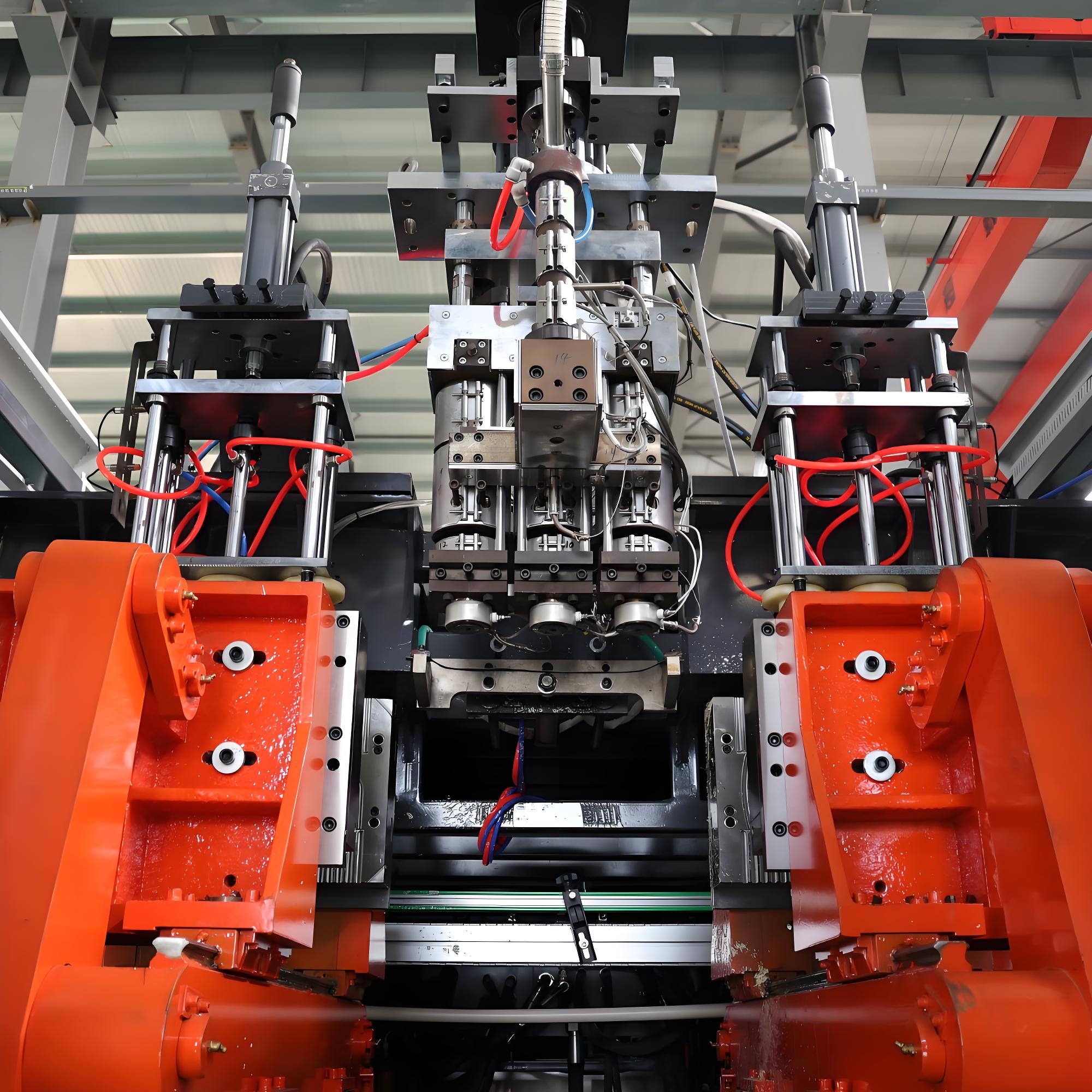

Features

Equiped with Japanese Mitsubishi PLC & temperature controller, Schneider contactor, Delta or ABB invertor, Siemens Motor, HITECH oil pump, Original Japan MOOG 100 points parison controller.

Die head inner runner adopt special steel mirror treatment, make sure PC products smooth surface and its transparent.

Mould temperature controller and neck cutting device is equiped special for PC products.

Detailed Parameters

| Tên | Units | ABLB 82 PC |

| Max. product volume | L | 25 |

| Dry cycle | PC/H | 360 |

| Screw diameter | MM | 82 |

| Screw L/D ratio | L/D | 25/30 |

| Screw drive power | KW | 10-80 |

| Screw heating capacity | KW | 30 |

| No. of heating zone | ZONE | 5 |

| Output of PC | KG/H | 160 (PC) |

| Oil pump drive power | KW | 45*2 |

| Clamping force | KN | 220 |

| Max. size of mold | MM | 1000×1600 |

| Template sze | MM | 800×800 |

| Die head heating power | KM | 8.7 |

| Total power consumption | KM | 83 |

| Blowing pressure | KG/CMZ | 8 |

| Air volume | M³/MIN | 0.8 |

| Cooling water temperature | ℃ | 5-10℃ |

| Average power consumption | KW | 42 |

| Size of machine | LxWxH | 5.6×2.7×4.5 |

| Weight of machine | TON | 11.8 |